Automated Warehouse Knowledge

What Are Autonomous Robots? Bringing Automation Into The Modern World Of Manufacturing And Logistics

In the context of the 4.0 industrial revolution taking place strongly, autonomous robots have become a hot topic attracting the attention of businesses, technologists and production managers. The integration of autonomous robot systems not only helps optimize processes and improve productivity, but also opens up many new possibilities in logistics management, transportation and automated production. Thanks to the development of sensor technology, artificial intelligence, and automatic control systems, autonomous robots are pioneers in the digital transformation revolution of today’s industries.

General introduction to autonomous robots

Today’s modern world of automation is inseparable from the presence of autonomous robots – robots capable of operating independently based on modern navigation and sensor systems. They not only contribute to reducing dependence on manual labor but also help businesses optimize processes, minimize risks as well as improve quality and productivity.

What is an autonomous robot?

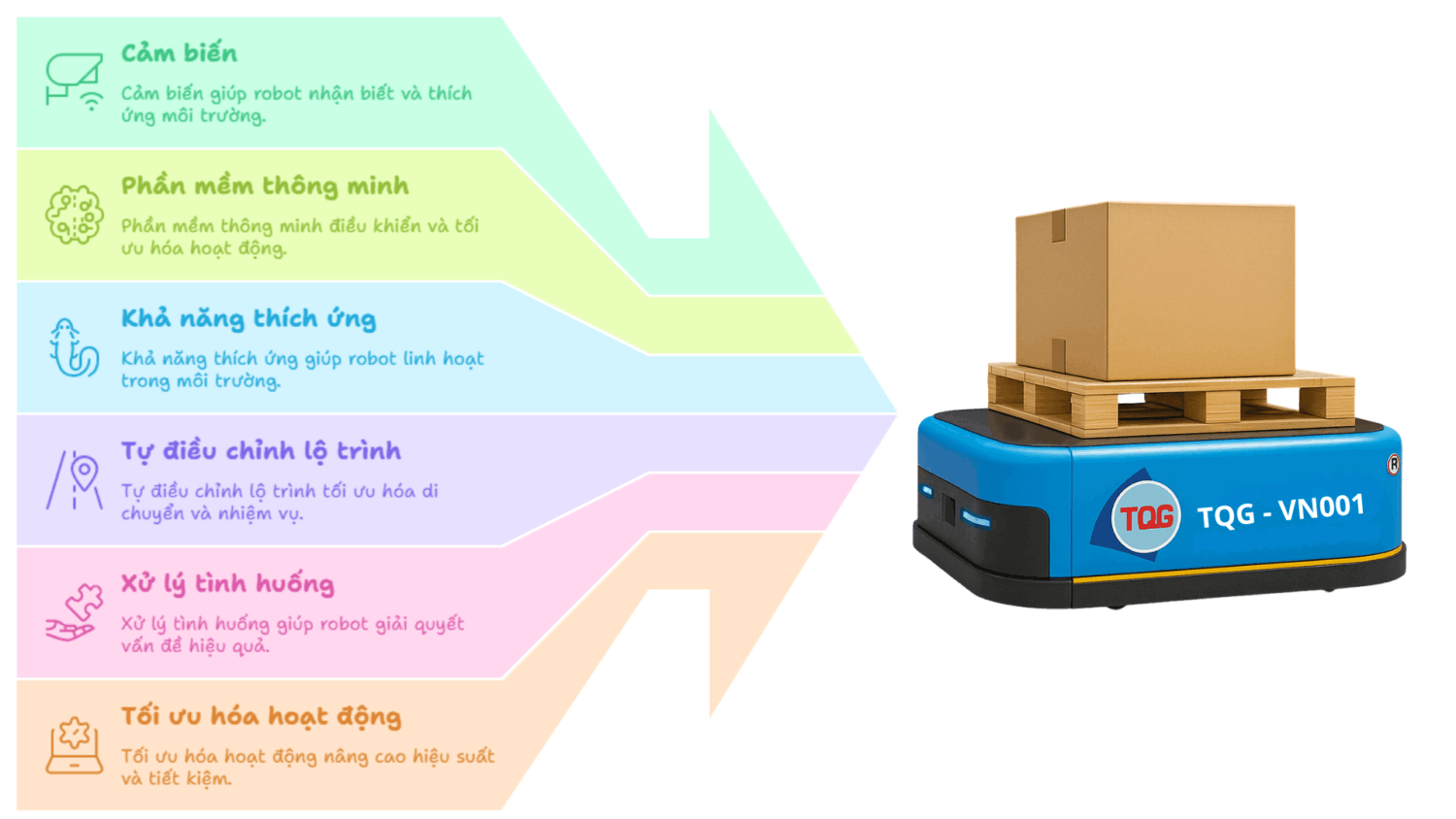

Autonomous robots are mechanical devices that are capable of moving and performing certain tasks without direct human control. The characteristics of these robots lie not only in their natural ability to operate but also in the integration of sensors and intelligent control software to adapt and behave flexibly in diverse working environments. In addition, they are also capable of self-adjusting routes, handling arising situations and optimizing operations based on real-world data.

In automated systems, autonomous robots bring many obvious benefits such as reducing labor costs, improving productivity and ensuring operational accuracy. Outstanding features include the ability to operate continuously, adapt quickly to environmental changes, have large payload capacity and operate in many different environmental conditions from heavy industry to electronics factories, logistics warehouses or shopping centers.

The role of autonomous robots in the modern context

As businesses increasingly move towards automation and digital transformation, autonomous robots play a decisive role in enhancing competitiveness and optimizing production processes. These robots are powerful assistants that help reduce the pressure on human resources, while expanding the unlimited operational capabilities of technology in all fields.

Not only do they replace heavy, dangerous manual labor, they also help ensure worker safety and increase accuracy in transporting and handling goods. In industries such as logistics, electronics, automotive, and heavy manufacturing, autonomous robots play a central role in the supply chain, from transporting raw materials to distributing finished products.

In addition, autonomous robots also help businesses improve efficiency significantly compared to traditional methods. Thanks to the ability to work continuously, accurately and quickly adapt to environmental changes, they contribute to creating a closed production process, optimizing time and resources to achieve the highest efficiency.

Popular types of autonomous robots on the market: AGV and AMR

Popular types of autonomous robots on the market: AGV and AMR

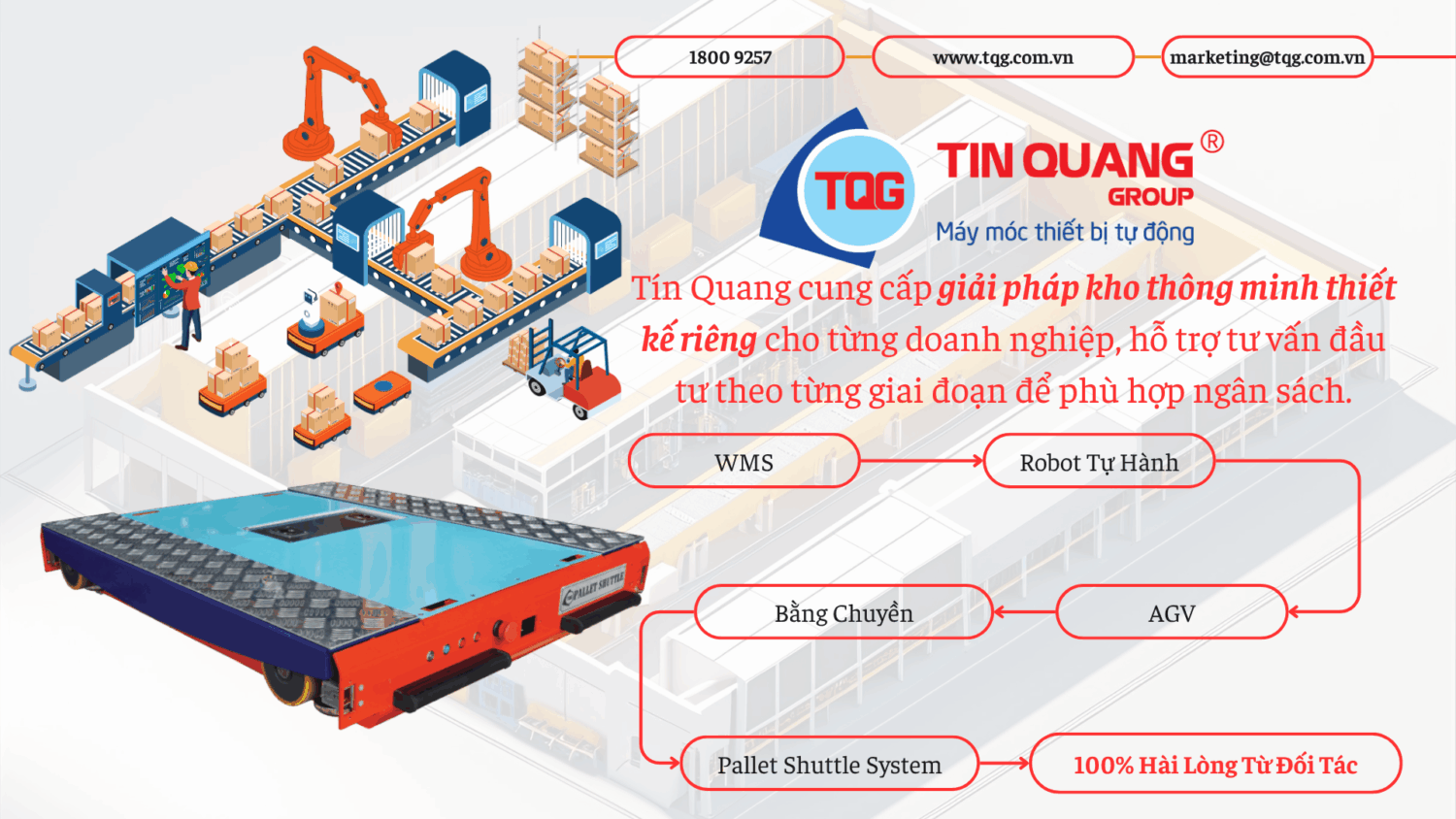

Currently, the world of autonomous robots is diverse and rich with many types suitable for different operating purposes. The two main types dominating the market are AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot). Each type has its own unique characteristics, suitable for specific applications in the manufacturing, logistics, warehousing and commercial industries.

Among them, AGV stands out with its ability to operate based on predetermined routes, suitable for transporting goods within a fixed range. In contrast, AMR possesses the ability to self-program and flexibly adapt to the environment, making it easy for them to operate in more complex spaces and without the need to design fixed routes. The common point of these two types is the ability to improve operational efficiency, reduce costs and ensure safety during operation.

Technology and systems related to autonomous robots

Autonomous robots cannot operate effectively without advanced supporting technologies. Sensor systems, programming software, artificial intelligence, and data security solutions play a vital role in ensuring their accuracy, safety, and efficiency.

Sensors and sensing devices support precise operation

Sensors are the core components that help autonomous robots interact, recognize their environment, and respond appropriately. Common types of sensors include laser scanning sensors, infrared sensors, optical sensors, ultrasonic sensors, and RFID sensors.

They provide data on terrain, location, obstacle avoidance, vehicle or other object detection. Thanks to that, robots can self-adjust their journey, avoid collisions, and maximize performance in complex operating environments. Sensors also help autonomous robots interact flexibly with the environment, thereby adapting to different conditions in factories or warehouses.

Automatic control systems and artificial intelligence in autonomous robots

The autonomous robot ‘s automatic control system is based on the integration of optimal algorithms, self-programmed operating controls and artificial intelligence. Thanks to this, the robot can self-learn and self-adapt based on process data, improving accuracy and flexibility in operation.

These systems also include the ability to analyze data, forecast trends, make optimal decisions in real time to minimize waiting times, optimize routes, and minimize resource waste. In addition, AI helps autonomous robots detect risks, handle problems quickly, self-repair, and operate continuously with little human intervention.

Automatic journey management and programming software

The software system for managing, controlling and programming the journey helps businesses easily configure, track and supervise the operation of autonomous robots . This software provides a friendly, easy-to-use interface, allowing for journey programming and customizing operating functions suitable for each production or logistics process.

Some software also integrates the feature of optimizing operations based on real-time data, helping to automatically adjust routes, minimize unnecessary travel, and increase operational efficiency. In addition, the system also supports predictive maintenance, early warning of errors to ensure continuous operation, minimizing downtime.

Security and data privacy in autonomous robot systems

In the digital age, data and automated control systems are both exposed to cybersecurity risks. Therefore, data security, information encryption, user authentication, and cyber-attack prevention have become indispensable items in autonomous robot systems .

Businesses need to develop policies to check and monitor system operations, update software regularly, and use advanced encryption tools to protect data. This security ensures continuous operations, avoiding financial damage, reputational damage, and the compromise of confidential business information.

Challenges and limitations of autonomous robots

Despite the many benefits, autonomous robots still face some major challenges related to cost, integration, and human capital. Understanding these limitations helps businesses develop the right strategy to maximize the technology and minimize risks.

Initial investment and system maintenance costs

Selecting and deploying autonomous robots requires a significant investment, including the cost of purchasing equipment, software, installation, operation and maintenance. In particular, high-end systems using AI, laser sensors, or integrated management software have even higher costs.

In addition, the cost of maintaining and upgrading the system also needs to be carefully calculated in the long-term project. Along with that is the requirement for a highly skilled technical team to undertake the maintenance, repair, and update of data and software necessary to keep the system operating stably and effectively.

Integration and synchronization issues with existing infrastructure

One of the major challenges is how to integrate autonomous robots into existing manufacturing or logistics systems without disrupting or affecting daily operations. This process requires adjustments to a company’s software, hardware, and operating procedures.

In reality, synchronization is difficult due to differences in software, equipment, technical standards and scalability of legacy systems. Therefore, businesses need to plan carefully and have appropriate transition steps to minimize risks, waste of resources and time.

Risk Management and Troubleshooting Solutions

Autonomous robots, no matter how advanced they are, can still encounter errors or problems during operation, such as collisions, faulty sensors, lost connections, or software issues. Therefore, businesses need to prepare contingency solutions, quick recovery procedures, and technical teams ready to intervene appropriately.

Setting up alert systems, monitoring operations continuously, and training employees with troubleshooting skills will help minimize downtime and avoid major financial or reputational damage to your business.

Train staff and adapt to new technology

A key challenge is how to adapt and effectively operate new autonomous robotic systems . This requires formal training programs that build on knowledge of autonomous technology, system administration, and new operating procedures.

A policy of continuous training, promoting a culture of innovation, testing new technologies, and building a highly skilled technical and operational team will help businesses maximize the potential of autonomous robots and minimize conflicts in the digital transformation process.

Development trends of autonomous robots in the future

Along with the advancement of science and technology, autonomous robots are expected to continue to develop strongly in the coming years, creating many breakthroughs in the fields of industry, logistics, services and consumers.

Upcoming Technological Advancements

New technologies such as artificial intelligence, deep learning, optical sensors, and the Internet of Things (IoT) will enable autonomous robots to self-program, self-learn, and adapt to more complex environments than ever before. Big data-based navigation, predictive and risk-prevention technologies will improve the accuracy and efficiency of autonomous systems.

In addition, research is also focusing on developing autonomous robots that can self-maintain, self-repair, minimize the possibility of errors and increase the life of the system. These advances will promote the widespread use of robots in new industries, transportation services, and even in people’s daily lives.

Multi-field application and market expansion

In the future, autonomous robots will not only be limited to heavy industries, warehousing or logistics, but will also expand to areas such as healthcare, automated agriculture, smart cities and public services. Diverse applications increase the possibility of expanding the market and demand for this technology.

Startups and large corporations are paying attention to that potential, stepping up research and developing suitable solutions to diversify applications, from fast urban transportation to supporting elderly care, or improving customer experience in consumer services.

The Impact of Autonomous Robots on the Workforce

Along with the benefits, autonomous robots also pose challenges in terms of impact on the workforce, especially in assembly line, transportation, and other highly replaceable occupations. On the one hand, they can reduce the number of direct workers involved in heavy, tiring processes; on the other hand, there is a need for career transition, retraining of higher-skilled workers to suit the new automated systems.

This requires businesses, governments and policymakers to establish training and skill-building programs that help workers adapt to new technologies while maximizing the benefits of automation in a sustainable manner.

Policies and strategies of businesses to maximize potential

To maximize the benefits of autonomous robots , businesses need to develop long-term strategies, make appropriate investments, and coordinate closely with technology suppliers, R&D facilities, and state management agencies. Supportive policies on taxes, investment, and technology transformation will help businesses minimize risks and take advantage of competitive advantages.

In addition, it is necessary to promote research, testing, and development of Japanese, Korean, or European solutions to enhance domestic capacity and strengthen international competitiveness in the field of autonomous robots. This combined policy will help the market develop healthily and sustainably, while bringing long-term economic, social, and environmental benefits.

Conclude

Autonomous robots are becoming an important element in the digital transformation and comprehensive automation of today’s businesses. From the ability to operate precisely, safely, flexibly to the ability to adapt flexibly in diverse environments, autonomous robot systems such as AGV or AMR contribute greatly to improving efficiency, minimizing costs, and creating a smart and sustainable production and logistics. However, facing and handling challenges in terms of costs, integration, and human resource training are still prerequisites for businesses to be able to exploit the full potential of this technology, towards a brighter future in the era of Industry 4.0.

Tiếng Việt

Tiếng Việt