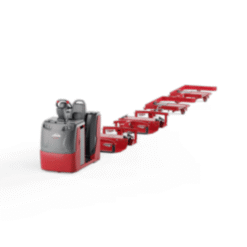

Linde’s LT10 – LT20 Logistic Trains

- Immobilizer active if trailers are lowered

- Cornering assistant helps to avoid tipping over

- Noise reduction due to elevated loads

- Small turning circle of less than four meters

- Directionally stable trailer steering

- Foot switch for lifting operation at the trailer

- Different trailer types for different containers

Swift Through Narrow Corridors

Linde’s LT10 – LT20 logistic trains are an efficient solution for bundling horizontal transports of large quantities of materials over longer distances, for example from a warehouse to several production lines. The three frame variants, C-Frames, B-Frames, and B-Frames with middle support can hold up to 2,000 kilograms, 1,000 kilograms, and 1,600 kilograms respectively, and offer the flexibility to combine different loads on one train. Whether pallets, grid boxes or small load carriers, transport goods of up to 2,000 kilograms per frame are maneuvered quickly, nimbly and with stability, even through narrow aisles and tight curves. The frames can be towed by either a manual or an automated tractor. Linde supports its customers with an optional tugger train guiding system for integration into digitally controlled processes and to ensure efficient use of the trains.

The standard opening side of the C-Frames is the right side. Optionally, the left side in the driving direction can also be chosen for a load exchange.

The Bridge-Frame can be equipped with a flexible middle support, which can be moved against the driving direction to the required position. This allows different load sizes to be handled with one frame type.

For outdoor applications, the frames can be equipped with robust super elastic (SE) wheels with a diameter of 250 mm and a width of 85 mm or 130 mm. These wheels are fully suspended which makes them perfectly suitable against vibrations.

There is a four-function LED taillight set with magnetic holder and two lights (indicator, taillights, brake lights, license plate light) available in clear glass. It provides sealed waterproof housing, e4 marking and assignment according to ISO 1724.

A flashing light can be located at the top of the trailer in order to make the logistic train visible, especially in dark areas.

A manually operated tarpaulin roof is available for the C-Frames with a one-sided opening and for the Bridge-Frames with a two-sided opening.

Linde offers trolleys in various designs. They form the interface between the load and the tugger train and can be equipped with modular racking superstructures, for example.

The tugger train guidance system coordinates the driving orders and provides the drivers with the optimal routes. The software dashboard shows all essential information at a glance and can be used to generate analyses for process optimization.

With the standard lock, the load can only be pulled out in the direction of the operator. With the push-through option, the trolley can be pushed out through the frame in both directions, making heavy loads easier to handle for the operator.

In addition to controlling the lift function via the display on the towing vehicle, the lift can also be controlled via a button on the frame.

Technical Data

Safety

In order to ensure the goods being transported are secure, it is not possible to start the train when the frames are lowered due to the starting lock and whilst traveling the lifting function is deactivated. Each frame also is equipped with a mechanical locking device that holds the load securely on the frames during travel. As soon as a container is placed on the frame, the lock closes automatically. The patented lifting mechanism of the forks has a tilt function that ensures the same ground clearance for all loaded trolleys, even with heavy loads. The all-wheel-steering allows a precise tracking behavior and avoids a pull out of the frames, which increases the safety in operational traffic.

- Load locking on all frames secures the transport goods

- Traveling prevention while frames are lowered

- Deactivated lifting function while driving

- Tilt function of the forks for same ground clearance, even with highest payloads

- All-wheel steering enables precise tracking behavior without pull out of the frames

Ergonomics

The logistic train offers an ergonomic solution for load handling through ground-level loading and unloading. All frame modules of the Linde logistic trains are connected to each other and to the tractor via data cables. The lift function can be controlled simultaneously for all frames as well as individually for each frame. The ergonomic ejection mechanism within the C-Frame pushes the load away from the back as soon as the driver releases the lock by foot. An option is available for the Bridge-Frames that allows the load to be removed from both sides. This allows the operator to push the load carrier through the frame, which reduces their heavy goods workload. Not only this. but the logistic trains run quietly thanks to the electric lifting function.

- Support for the driver through simultaneous and individual lifting

- Ergonomic ejection mechanism on C-Frame and optional push-through on Bridge-Frame simplify the handling of heavy loads

- Low noise emission

Handling

The frames are equipped with a mechanical all-wheel steering. This allows the logistic trains to be maneuvered extremely precisely. They are characterized by small turning circles, directional stability, and tipping stability. The frame modules are available as C-, Bridge- and Bridge-Frames with adjustable middle support, which are automatically raised for transport and lowered again for unloading. This speeds up loading and unloading. By moving the middle support, different load sizes can be transported in one frame. The patented lifting profile mechanism also allows pallets to be picked up without a rolling load carrier if for example these have been placed in the frame with a pallet truck. The optional tugger train guiding system determines the optimal route, reduces error rates and training times, and responds to order changes in real-time.

- All-wheel steering for small turning circles and high directional stability

- Fast lift function when getting on and off

- Adaptation to different transport goods due to movable middle support

- Patented lifting profile mechanism allows pallets to be transported without a rolling load carrier

- Optional tugger train guiding system for integration into digital processes

Service

The current status of the connected frames is visualized on the touch display at the driver’s station. The lifting motors on the frames are maintenance-free and electrically monitored in order to guarantee safe transportation in every situation. The tow bar in combination with the coupling ball hook is almost wear-free. The two-axle design with a central load space also ensures an easy access for maintenance. Each frame is equipped with its own hour counter. This facilitates maintenance planning for the overall combination of tractors and frames. Standardized interfaces with predefined functions allow the frames to be used in conjunction with manual or automated tow tractors at any time without the need for retrofitting.

- Current status of each frame visualized on touch display

- Maintenance-free and electronically monitored lift motors

- Largely wear-free tillers and couplings

- Easily accessible and low-maintenance design of the frames

- Hour counter for each frame facilitates maintenance planning

- Prepared for automation through standardized interfaces

Linde Brand

At Linde Material Handling, we develop high-performance material flow solutions tailored to individual customer needs, enabling users to achieve sustainable competitive advantages. In over 120 years of company history, Linde MH has become one of the world’s largest manufacturers of forklifts and warehouse equipment. With innovations such as the hydrostatic drive and highly effective assistance systems, we are the technology leader in the industry.

We also offer services and solutions for intralogistics and have been setting standards in the areas of industrial trucks, fleet management, driver assistance systems, and service offerings for more than 70 years. As a global provider of solutions for internal material flow, we are part of the KION Group, a leading global intralogistics group.

Sản Phẩm Cùng Loại

Logistic Trains

Tiếng Việt

Tiếng Việt